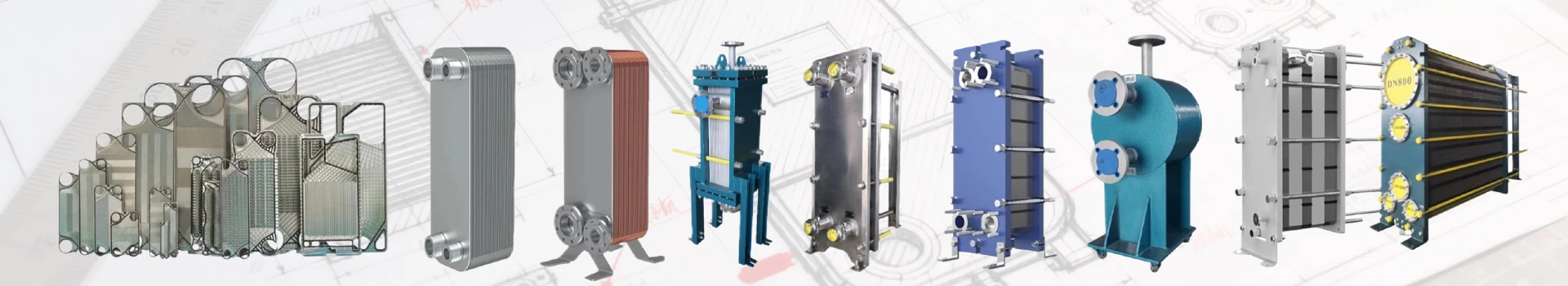

Wide-Channel Plate Heat Exchangers

The wide-channel plate heat exchanger is a specialized heat exchange equipment designed to handle highly polluted, high-viscosity media containing solid particles. Its unique wide-channel design and corrosion-resistant materials demonstrate significant performance in industries such as wastewater treatment, chemical engineering, food processing, and papermaking. This article provides a detailed introduction to the core advantages, application scenarios, and customer value of the wide-channel plate heat exchanger, helping you better understand this product.

I. Core Advantages of Wide-Channel Plate Heat Exchangers

1. Unique Wide-Channel Design

- Large Channel Width: Channel width is 2-3 times that of conventional plate heat exchangers, effectively preventing clogging.

- Adaptability to Highly Polluted Media: Suitable for handling media containing solid particles, fibers, sludge, and other highly polluted substances.

2. Rapid Heat Exchange

- Corrugated Plate Design: The corrugated structure on the plate surface enhances fluid turbulence, improving heat exchange efficiency.

- High Heat Transfer Coefficient: Offers a 20%-30% improvement in heat transfer efficiency compared to traditional shell-and-tube heat exchangers.

3. Strong Corrosion Resistance

- Superior Materials: Utilizes corrosion-resistant materials such as stainless steel, titanium alloys, and Hastelloy, suitable for acidic, alkaline, and saline media.

- Long Service Life: Maintains stable long-term operation even under harsh conditions.

4. Easy Maintenance

- Detachable Design: Plate assemblies can be easily disassembled for cleaning and maintenance.

- Self-Cleaning Function: The wide-channel design reduces fouling buildup, lowering cleaning frequency.

5. Energy-Saving and Eco-Friendly

- Rapid Heat Exchange: Reduces heat loss and lowers energy consumption.

- Waste Heat Recovery: Enables recovery of heat from wastewater, improving energy utilization.

6. Strong Adaptability

- Versatility with Media: Applicable to heat exchange between liquid-liquid, gas-liquid, steam-liquid, and other media types.

- Suitability for Various Conditions: Adapts to complex conditions such as high temperature, high pressure, and high viscosity.

II. Application Scenarios of Wide-Channel Plate Heat Exchangers

1. Wastewater Treatment Industry

- Wastewater Heat Recovery: Recovers heat during wastewater treatment processes, reducing energy consumption.

- Sludge Heating: Used for heating sludge to improve dewatering efficiency.

2. Chemical Industry

- Heat Exchange with Highly Polluted Media: Handles media containing solid particles and fibers.

- Heat Exchange with Corrosive Media: Suitable for acidic, alkaline, and saline corrosive media.

3. Food Industry

- Heat Exchange with High-Viscosity Media: Used for high-viscosity media such as juice, jam, and syrup.

- Heat Exchange with Particle-Containing Media: Suitable for media with pulp or fibers.

4. Papermaking Industry

- Black Liquor Processing: Used for evaporative concentration of black liquor, recovering chemicals.

- Wastewater Treatment: Handles high-temperature treatment of paper making wastewater to ensure compliant discharge.

5. Environmental Protection Industry

- Landfill Leachate Treatment: Processes high-temperature landfill leachate, recovering heat energy.

- Industrial Wastewater Treatment: Handles heat exchange for highly polluted industrial wastewater.

III. Features of Wide-Channel Plate Heat Exchangers

1. Reduced Operating Costs

- Energy Savings and Consumption Reduction: Rapid heat exchange and waste heat recovery significantly lower energy use, saving operational costs.

- Reduced Maintenance Expenses: Wide-channel design and detachable structure decrease cleaning and maintenance frequency.

2. Improved Production Efficiency

- Rapid Heat Exchange: Fast heat transfer boosts production efficiency.

- Stable Operation: Corrosion-resistant materials and wide-channel design ensure long-term equipment stability.

3. Environmental Compliance

- Reduced Emissions: Waste heat recovery and rapid processing reduce wastewater discharge, meeting environmental standards.

- Resource Recovery: Recovers heat energy from wastewater, enabling resource reuse.

4. Flexible Adaptability

- Suitability for Various Conditions: Adapts to complex conditions involving high pollution, high viscosity, and solid particles.

- Customized Design: Equipment specifications and materials can be tailored to client needs, meeting specific condition requirements.

IV. Practical Application Cases of Wide-Channel Plate Heat Exchangers

Case 1: Waste Heat Recovery Project at a Wastewater Treatment Plant

A wastewater treatment plant generating large amounts of high-temperature wastewater adopted a wide-channel plate heat exchanger for waste heat recovery. After treatment, the wastewater temperature dropped from 80°C to 40°C, with the recovered heat used to warm incoming cold water, saving approximately 500,000 yuan annually in energy costs.

Case 2: High-Pollution Media Processing Project at a Chemical Plant

A chemical plant producing large amounts of highly polluted media containing solid particles used a wide-channel plate heat exchanger. After treatment, the media temperature decreased from 60°C to 30°C. The equipment operated stably without clogging issues, improving production efficiency by 20%.

V. OUDUN Service Commitment

1. Design

Provides customized design solutions based on client needs, ensuring equipment meets actual operating conditions.

2. High-Quality Manufacturing

Utilizes premium materials and advanced craftsmanship to ensure high performance and long lifespan.

3. Rapid Delivery

A streamlined supply chain and production process ensure timely equipment delivery.

4. After-Sales Service

Offers comprehensive services including installation, commissioning, operator training, and regular maintenance, ensuring customer peace of mind.

Welcome To Visit Our Official Website!

If you have any questions, please contact us through the following ways, we will give you the most sincere service!