Double-flow Plate Heat Exchangers

Double-flow plate heat exchangers achieve rapid heat transfer and compact design through a dual-pass fluid flow configuration between plates, widely used in chemical engineering, HVAC, food and pharmaceutical industries. This article provides an in-depth analysis of its technical features, advantages, and application scenarios to assist users in making informed selections.

I.Technical Structure and Working Principle of Double-Flow Plate Heat Exchangers

1. Structural Composition

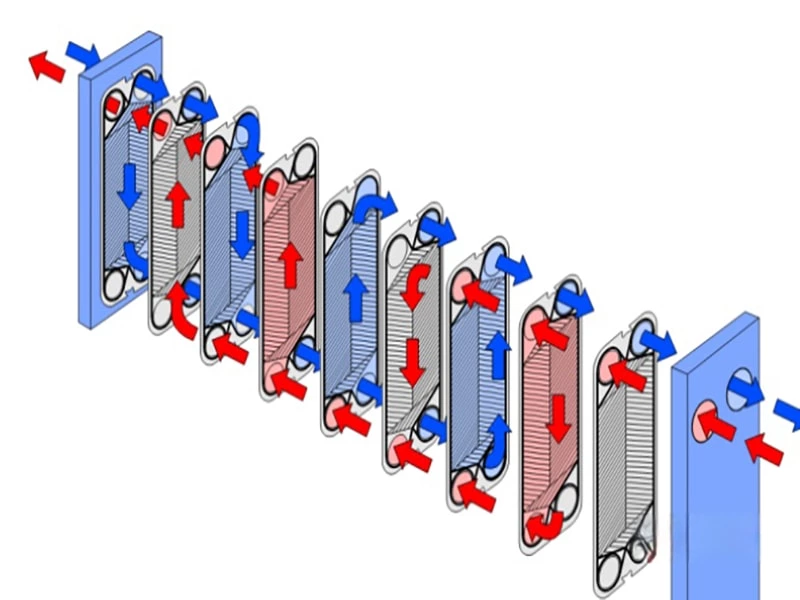

Composed of corrugated plates (e.g., herringbone or diagonal corrugations), gaskets, fixed compression plates, and movable compression plates. Independent flow channels for hot and cold media are formed between plates, with fluids flowing alternately on both sides to facilitate heat exchange.

2. Principle of Dual-Flow Design

Fluid enters the plate bundle through distribution ports and flows back twice between plates, forming two parallel flow paths (e.g., 1234 or ABCD paths). Compared to single-flow designs, the dual-flow configuration extends the fluid path, increases contact time and heat transfer area, enhancing heat exchange efficiency.

II. Core Advantages of Double-Flow Plate Heat Exchangers

1. Rapid Heat Transfer Performance

Heat transfer coefficient can reach 3000-6000 W/(m²·℃), suitable for large temperature difference conditions (ΔT ≥ 20℃). The dual-flow design ensures more uniform fluid velocity, reduces turbulent dead zones, and lowers thermal resistance.

2. Compact Structural Design

Occupies only one-third the volume of traditional shell-and-tube heat exchangers for the same heat transfer area, saving installation space. Ideal for space-constrained industrial scenarios (e.g., marine equipment, modular units).

3. Accurate Temperature Control

The dual-flow design enables a more stable temperature gradient distribution, suitable for processes with strict outlet temperature requirements (e.g., pharmaceutical reaction cooling).

4. Easy Maintenance

Detachable structure design allows for easy cleaning and plate replacement, reducing downtime. Gaskets are replaceable, extending equipment lifespan.

III. Key Technical Parameters of Double-Flow Plate Heat Exchangers

1. Parameters: Typical Range

2. Flow Paths:** 2 (dual-flow)

3. Design Pressure:** ≤ 2.5 MPa (customizable for high-pressure models)

4. Design Temperature:** -40℃ to 200℃

5. Plate Material:** Stainless steel (304/316L), titanium, Hastelloy, etc.

6. Heat Transfer Coefficient:** 2000-5000 W/(m²·℃)

7. Single Plate Area:** 0.1-1.2 m²

8. Maximum Capacity:** 5000 m³/h (per unit)

IV. Application Scenarios and Case Analysis of Double-Flow Plate Heat Exchangers

1. HVAC

*Geothermal Heat Pump Systems:** Utilizes dual-flow heat exchangers to rapidly extract geothermal energy, improving system COP.

*Air Conditioning Cooling Towers:** Handles large flows of cooling water, achieving energy savings and consumption reduction.

2. Chemical and Pharmaceutical

*Reactor Temperature Control:** Dual-flow enables precise temperature control, ensuring chemical reactions occur within the set temperature range.

*Solvent Recovery:** Processes media with large temperature differences (e.g., 120℃ to 40℃), recovering waste heat.

3. Food and Beverage

*Milk Instant Pasteurization:** Low temperature rise (ΔT ≤ 5℃) preserves nutritional content.

*Beer Brewing:** Rapid cooling of wort shortens fermentation cycles.

V. Key Points for Selecting Double-Flow Plate Heat Exchangers

1. Heat Load and Temperature Difference

Prioritize dual-flow for large temperature differences (≥ 30℃) or high heat transfer demands. Use the NTU-ε method to calculate the number of flow paths, ensuring heat exchange efficiency.

2. Fluid Characteristics

Select wide-channel plates (e.g., large-gap type) for high-viscosity media to avoid clogging. Use titanium or Hastelloy for corrosive media to extend service life.

3. Space Constraints

Compact equipment favors dual-flow designs, reducing footprint costs. Consider equipment hoisting and maintenance space, reserving a 30% operational margin.

4. Economic Considerations

Initial investment is higher than single-flow designs, but long-term energy savings are significant, making it suitable for continuous operation scenarios.

VI. Common Issues and Solutions for Double-Flow Plate Heat Exchangers

1. Excessive Pressure Drop

Optimize plate corrugation design (e.g., adopt M-type channels) to balance flow velocity and resistance. Increase the number of parallel flow paths to reduce single-path flow.

2. Scaling and Clogging

Select easily cleanable plate types (e.g., herringbone corrugations) and perform regular CIP cleaning. Install pre-filters for media with particles to prevent channel blockages.

3. Leakage Risk

Use high-temperature- and corrosion-resistant gasket materials (e.g., EPDM, PTFE). Regularly check clamping force to ensure sealing stability.

VII. Future Trends of Double-Flow Plate Heat Exchangers

1. Rapidization

Develop new corrugation structures (e.g., 3D-printed plates) to further enhance heat transfer coefficients.

2. Intelligence

Integrate sensors and AI control for real-time optimization of operating parameters.

3. Modularization

Standardized designs support parallel or series combinations, enabling flexible capacity expansion.

Summary: Double-flow plate heat exchangers demonstrate significant advantages in rapid heat transfer, compact structure, and precise temperature control across various industries. Selection should align with specific operating conditions, balancing efficiency, cost, and maintenance needs to maximize technical value.

Welcome To Visit Our Official Website!

If you have any questions, please contact us through the following ways, we will give you the most sincere service!