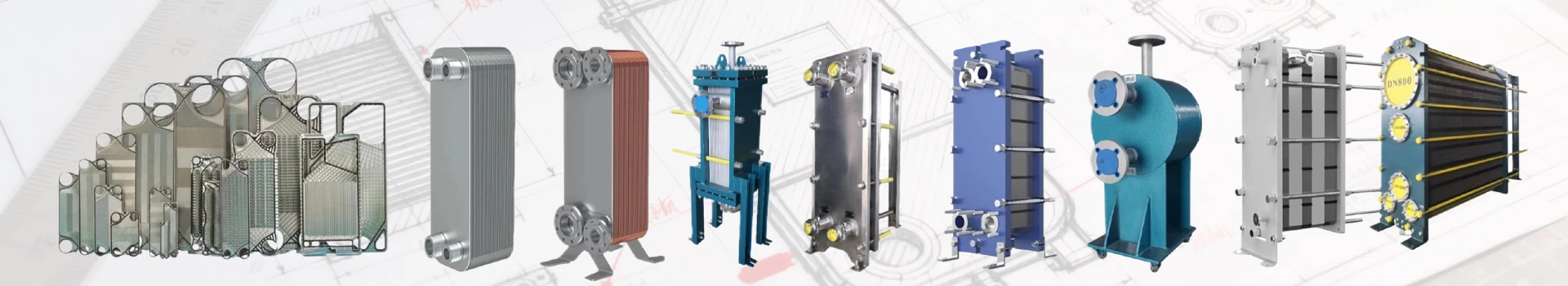

Steam / Water Plate Heat Exchangers

Publish Time:

Steam-Water Plate Heat Exchanger: Overview and Applications

1. Working Principle

The steam-water plate heat exchanger facilitates heat transfer from steam to water for heating or cooling purposes:

- Steam Inlet: Steam enters through the upper inlet and is distributed across parallel metal plates.

- Heat Transfer: Steam flows on one side of the plates, transferring heat to water on the opposite side via highly conductive materials (e.g., stainless steel or titanium). Corrugated plate surfaces enhance turbulence, boosting heat transfer efficiency.

- Condensation and Water Heating: Steam condenses into water, which is discharged through dedicated pipes. Water absorbs the released heat, increasing its temperature.

- Water Outlet: Heated water exits for use in subsequent processes or heating systems.

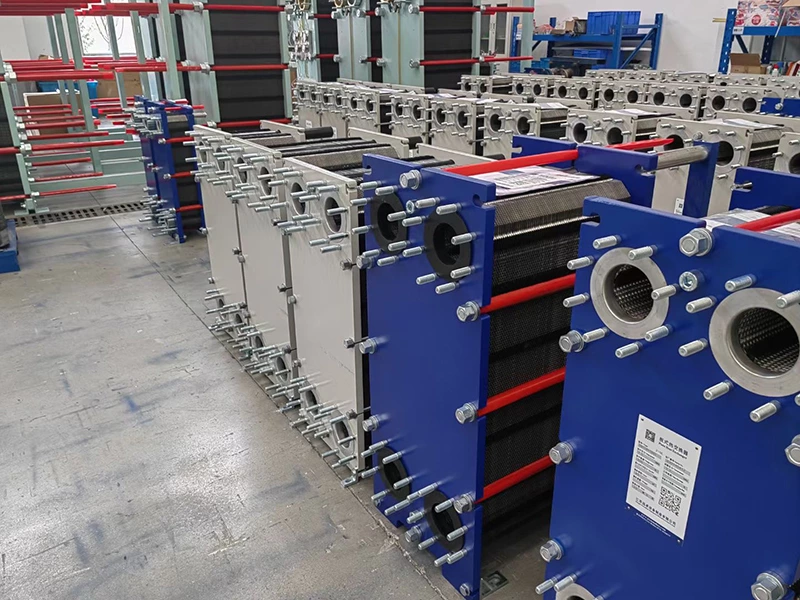

2. Structural Features

- Plates: Core components made of corrosion-resistant materials like stainless steel or titanium. Corrugated surfaces enhance turbulence and heat transfer. Plates are sealed with gaskets or welding to prevent fluid mixing.

- Frame: A robust metal frame secures plates and provides fluid inlet/outlet channels.

- Flow Path Design: Steam and water flow through separate channels, configured as parallel, counterflow, or crossflow. Counterflow designs typically maximize heat transfer efficiency.

- Sealing System: Gaskets or welds prevent leaks and fluid mixing, with materials selected based on fluid properties and operating temperatures.

3. Advantages

- High Thermal Efficiency: Corrugated plates and high heat transfer coefficients yield efficiency 3-5 times greater than traditional shell-and-tube exchangers.

- Compact Design: Small footprint, ideal for space-constrained environments.

- Flexibility: Adjustable plate numbers allow scalable heat transfer capacity.

- Ease of Maintenance: Plates are easily disassembled for cleaning.

- Energy Efficiency: Effective heat recovery reduces energy waste and operational costs.

4. Applications

- Industrial Processes: Heats or cools materials in reactors and columns for chemical, pharmaceutical, and food industries.

- Energy Recovery: Recovers waste heat, transferring it from high-temperature steam to low-temperature fluids.

- Building and HVAC: Supplies hot water for domestic or heating systems.

- Seawater Desalination: Preheats seawater to enhance desalination efficiency.

5. Selection Considerations

- Heat Load: Calculate required heat load to determine heat transfer area.

- Fluid Properties: Assess temperature, pressure, flow rate, and corrosiveness to select appropriate plate and sealing materials.

- Operating Conditions: Ensure design pressure and temperature meet process requirements.

- Installation Space: Choose a suitably sized exchanger for site constraints.

- Maintenance: Prioritize designs that facilitate easy disassembly and cleaning.

Welcome To Visit Our Official Website!

If you have any questions, please contact us through the following ways, we will give you the most sincere service!