Application of BPHE in Screw Compressors

Brazed plate heat exchangers, with their efficient heat exchange performance and compact structure, are widely used in industrial applications, particularly in screw compressor systems. As a highly efficient compression device, screw compressors are extensively employed in refrigeration, air conditioning, chemical processing, and natural gas processing, with their performance heavily reliant on effective thermal management. Brazed plate heat exchangers, with their unique design and excellent performance, have become an indispensable component in screw compressor systems.

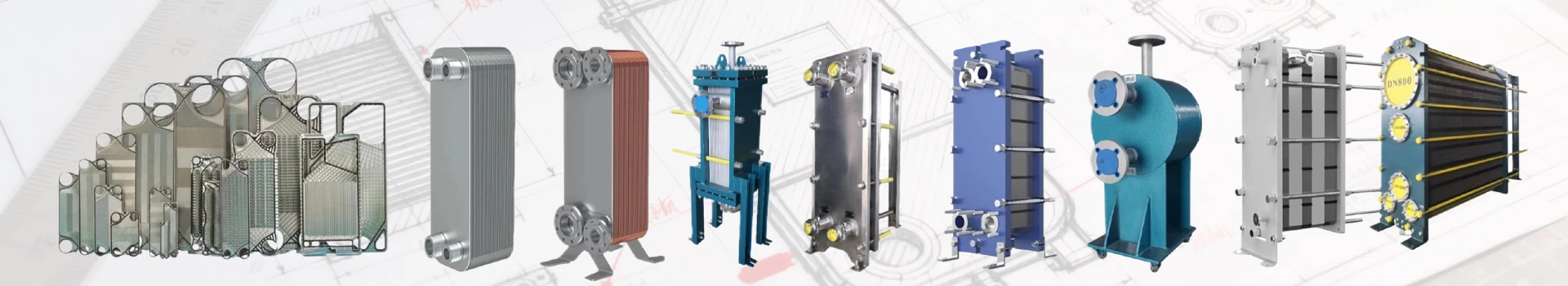

I. Structure and Features of Brazed Plate Heat Exchangers

Brazed plate heat exchangers are made from materials such as copper or stainless steel, with multiple plates or tube bundles securely joined through a high-temperature brazing process. Their compac t structure, lightweight design, and high heat exchange efficiency are key features:

- High Heat Transfer Coefficient: The microchannel design between plates offers heat transfer efficiency several times that of traditional heat exchangers.

- Strong Pressure Resistance: Capable of withstanding pressures up to 4.5 MPa, suitable for high-pressure conditions.

- Leak-Proof Design: The brazing process ensures leak-free joints, enhancing system reliability.

II. Advantages in Screw Compressor Applications

- Efficient Condensation and Vaporization Serving as condensers or evaporators, brazed plate heat exchangers rapidly condense high-temperature, high-pressure gases discharged by the compressor into liquids or vaporize low-temperature liquids into gases. Their high heat transfer coefficient significantly reduces heat exchange time, improving overall compressor efficiency.

- Compact Design Screw compressors are often used in space-constrained settings (e.g., marine or mobile equipment), and the brazed plate heat exchanger’s volume is only one-third that of traditional shell-and-tube heat exchangers, making it an ideal fit.

- Energy Savings By optimizing the heat exchange process and reducing energy loss, brazed plate heat exchangers lower the operating energy consumption of screw compressors, particularly in continuous industrial operations.

- Corrosion Resistance and Longevity Made from stainless steel or copper, brazed plate heat exchangers resist corrosion from refrigerants and lubricants, ensuring stable long-term operation under harsh conditions.

III. Specific Functions and Applications

- Condenser Role: In refrigeration systems, brazed plate heat exchangers cool and condense high-temperature refrigerant gases discharged by the compressor, maintaining system pressure balance.

- Oil Cooling: High-temperature lubricating oil generated during compressor operation is cooled by brazed plate heat exchangers, preventing overheating damage.

- Economizer Function: In certain high-efficiency refrigeration cycles, brazed plate heat exchangers serve as economizers, enhancing cycle efficiency.

IV. Practical Application Case

A major refrigeration equipment manufacturer integrated brazed plate heat exchangers as condensers in its screw compressor systems. Compared to traditional shell-and-tube heat exchangers, the system achieved a 15% improvement in condensation efficiency, a 10% reduction in energy consumption, and showed no leaks or performance degradation after 12 months of continuous operation.

V. Conclusion

With their efficiency, compactness, and durability, brazed plate heat exchangers demonstrate significant advantages in screw compressor applications. Their use in condensation, oil cooling, and economizer functions not only enhances compressor performance but also reduces operating costs. For industrial applications requiring high efficiency and reliability, brazed plate heat exchangers are an ideal choice.

Welcome To Visit Our Official Website!

If you have any questions, please contact us through the following ways, we will give you the most sincere service!