Application Of All Stainless Steel Fursion Welded Phe In The Lithium Battery Industry

Stainless steel welded plate heat exchangers, with their excellent corrosion resistance and efficient heat exchange performance, play a vital role in the lithium battery manufacturing industry. The production of lithium batteries involves complex chemical reactions and stringent temperature control requirements, and stainless steel welded plate heat exchangers, with their unique design and durability, have become indispensable equipment in battery production. Notably, the all-stainless steel welded design eliminates copper ion contamination, which is critical for maintaining a pure environment in lithium battery manufacturing.

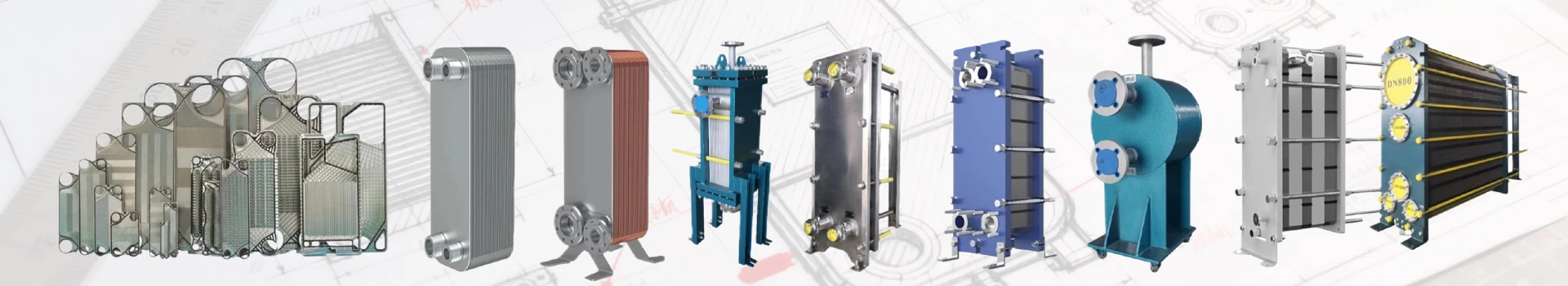

I. Structure and Features of Stainless Steel Welded Plate Heat Exchangers

Stainless steel welded plate heat exchangers are constructed by welding stainless steel plates or tube bundles together using a welding process, forming leak-free heat exchange channels. Their key features include:

- Excellent Corrosion Resistance: Made from 304 or 316L stainless steel, they resist corrosion from acids, alkalis, and electrolytes.

- High-Strength Structure: The welding process ensures the equipment can withstand pressures up to 6 MPa, suitable for high-temperature and high-pressure conditions.

- Efficient Heat Transfer: Plate design enhances turbulence, with heat transfer coefficients reaching 4000-6000 W/(m²·℃).

- Elimination of Copper Ion Contamination: The all-stainless steel construction removes the risk of copper material contamination, ensuring purity during lithium battery production.

II. Advantages in the Lithium Battery Industry

- Precise Temperature Control The preparation of electrolytes and cell formation in lithium battery production require strict temperature management. The high heat transfer performance of stainless steel welded plate heat exchangers ensures process temperatures remain stable within ±1℃.

- Corrosion Resistance The strong acids, alkalis, and electrolytes used in lithium battery production pose significant corrosion challenges, and stainless steel materials effectively extend equipment lifespan.

- Compact and Efficient Compared to traditional heat exchangers, their compact design saves factory space, while high heat transfer efficiency reduces energy consumption, aligning with the green manufacturing trends in the lithium battery industry.

- Easy to Clean and Maintain The welded structure minimizes dead zones, facilitating cleaning and meeting the strict cleanliness requirements of lithium battery production.

III. Specific Functions and Applications

- Electrolyte Cooling: During electrolyte preparation, welded plate heat exchangers rapidly cool high-temperature mixtures, preventing uncontrolled chemical reactions.

- Battery Module Thermal Management: Used for heating or cooling battery modules to ensure uniform temperatures during charge-discharge cycles.

- Waste Heat Recovery: Recovers waste heat from production processes for preheating raw materials or heating workshops.

IV. Practical Application Case

A lithium battery manufacturer implemented stainless steel welded plate heat exchangers for electrolyte cooling in its production line. Compared to traditional shell-and-tube heat exchangers, cooling efficiency improved by 20%, energy consumption decreased by 15%, and the equipment showed no signs of corrosion or leakage after six months of continuous operation.

V. Conclusion

With their corrosion resistance, efficient heat transfer, and compact design, stainless steel welded plate heat exchangers demonstrate significant advantages in the lithium battery industry. The all-stainless steel construction eliminates copper ion contamination, further ensuring a pure production environment. Their applications in electrolyte processing, thermal management, and waste heat recovery not only enhance production efficiency but also support green manufacturing goals. For lithium battery manufacturers, choosing stainless steel welded plate heat exchangers is an effective way to optimize processes and reduce costs.

Welcome To Visit Our Official Website!

If you have any questions, please contact us through the following ways, we will give you the most sincere service!