Hastelloy Plate Heat Exchangers

Hastelloy Plate Heat Exchangers possess excellent corrosion resistance and have been widely applied in various harsh environments and industries. The following are the key points:

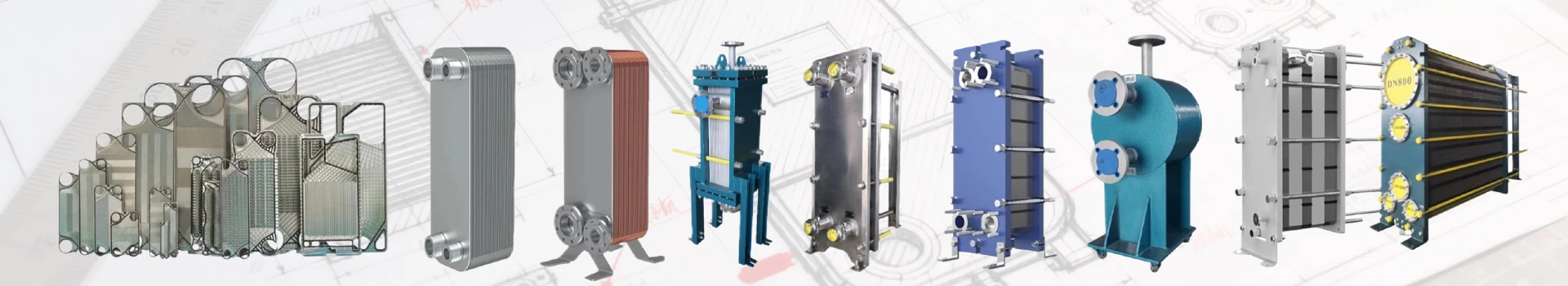

1. Classification of Hastelloy Plate Heat Exchangers

Hastelloy heat exchangers are available in several types, including shell-and-tube, double-tubesheet, and plate heat exchangers. Among them, the fully welded Hastelloy plate heat exchanger is one of the most widely used variants.

2. Structure of Hastelloy Plate Heat Exchangers

The structure of this heat exchanger is simple, consisting primarily of welded plates. These plates are densely patterned with heating and cooling channels, enabling rapid heat transfer between the hot and cold media.

3. Working Principle of Hastelloy Plate Heat Exchangers

The fully welded Hastelloy plate heat exchanger operates on the principle of heat conduction. Through its plate structure, it facilitates efficient heat exchange between the two media. The high thermal conductivity and superior corrosion resistance of Hastelloy alloy ensure excellent performance during the heat transfer process.

4. Pricing of Hastelloy Plate Heat Exchangers

Owing to the use of high-cost premium materials, fully welded Hastelloy plate heat exchangers command a relatively high price. However, considering their superior heat transfer efficiency and long service life, the cost is generally considered acceptable.

5. Features of Hastelloy Plate Heat Exchangers

Hastelloy plate heat exchangers are characterized by:

- High heat transfer efficiency

- Excellent corrosion resistance

- Compact size

- Lightweight construction

- Small footprint

- Easy installation and maintenance

6. Application Fields of Hastelloy Plate Heat Exchangers

Hastelloy plate heat exchangers are extensively used in the following industries:

- Chemical processing

- Petroleum and natural gas

- Food and beverage

- Power generation

- Pharmaceutical

- Textile

- Pulp and paper

- Marine engineering / offshore applications

7. Practical Case Study

OUDUN successfully delivered 4 units of Hastelloy plate heat exchangers to a chemical plant for the circulating cooling process of 98% concentrated sulfuric acid.

The outstanding corrosion resistance of Hastelloy plate heat exchangers gives them broad application potential across multiple industrial sectors, particularly in environments involving highly corrosive media or high-temperature operating conditions.

Welcome To Visit Our Official Website!

If you have any questions, please contact us through the following ways, we will give you the most sincere service!